Your Current Position: PRODUCTS > Intelligent equipment

Search

Overhaul and Repair of Mixer

We can overhaul and repair all types of Internal Mixer/Banbury at home and abroad. Provide one-stop service of disassembly, maintenance, renovation, installation, commissioning and spare parts. Rotor, mixing chamber, discharging door and movable/fixed ring surfacing are advanced welding alloy technology. It can reach no crack standard.

Online Upstream Equipment

The system is a highly automated and intelligent material weighing feed system developed for the rubber industry.

Off-line Upstream Equipment

The system is designed and developed for customers with low factory buildings, large variety of powder materials and complex formulas. Using screw feeder automatic feed, weighing moving car, automatic in place, circular conveying.

Pneumatic Conveying System

A method of transporting materials by the flow of gas in a pipeline to transport the materials to a positioning bin.

Automatic small chemical weighing system

This system can be group controlled at the same time using multiple scales. It controlled by computer network management, with recipe management, recipe running, date report, plan management, material statistics, alarm record and action chain, etc.

Semi-auto small chemical weighing system

The storage bins will be transported automatically according to the recipe, and the feeding, the weighing and the refilling the material into the storage bin are operated manually in the semi-automatic pigment weighing system.

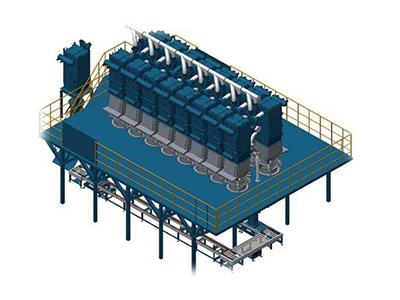

AUTOMATIC MIXING PRODUCTION LINE

The automatic mixing production line belongs to the auxiliary machine of the internal mixer, which is used to replace the original mixing and final mixing process. It can reduce labor, improve automation, improve the quality of rubber and save energy.